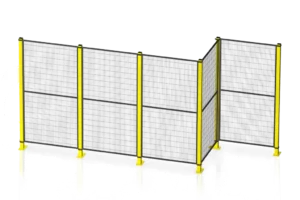

There are many types of USA Machine Guards available, including fixed, adjustable and self-adjusting. Here, we’ll discuss the benefits of each and how to choose the right one for your machine. The fully framed panel offers added strength and stability. The angle frame design allows clear access to all mounting hardware and speeds up installation. This heaviest mounting hardware is the industry standard. Learn more about the advantages of each type of guard.

Machine Guards Interlocked

When you choose an interlocked Machine Guards, you’ll benefit from a few factors, including its design and installation. The safety distance must be sufficient to prevent a person from entering the machine from behind. The guard must also be located in a safe location. OSHA machine guard regulations, available from Interlocked USA, are a comprehensive set of guidelines for general industry. The OSHA app, for example, contains all the regulations that apply to industrial machine guards.

An interlocked machine guard can be hard to bypass with easily-available objects. This means that it may require special keys or actuators to bypass. The interlock may also have physical, electrical or magnetic interlocking devices that block access to the machine when the guard is open. Ultimately, the safety of your workers depends on the interlocked machine guards you choose. Interlocked guards are best if the removable machine guards are interlocked.

Machine guards: protect operator

Machine guards protect the operator and other employees from harm caused by dangerous moving parts. Machine guards are used to protect from flying chips, ingoing nip points, rotating parts, reciprocating parts, and transversing mechanisms. Guards are physical barriers that limit access to a hazardous area. These guards may also contain automated feeding and ejection mechanisms that limit the exposure of the operator to the point of operation.

Machine guards can also incorporate a presence sensing device that will prevent a person from activating the controls. An example is the deadman control on a modern snow thrower. This system will place the snow thrower in a safe position when the operator leaves the controls. Similarly, an additional control valve will provide the normal control mode. If an interlock device is not integrated with a monitoring system, then it will not operate safely.

Fixed

Safety should be a priority, and there are several ways to ensure that it’s accomplished. The most important step is to design the machine with safety in mind. Built-in guards reduce the risk of exposure and also minimize the need for supervisory personnel and training. To achieve the best possible result, safety should be considered from the initial engineering stage, including the machine’s design and plant layout. The responsibility for safety extends beyond the design of the machine, and should include the selection of materials and time study techniques. Unfortunately, even minor modifications or unforeseeable circumstances can affect the performance of built-in guards.

In addition to keeping the operator safe, machine guards should prevent debris from falling into the moving parts of the machine. This will minimize the risk of accidents and injuries due to human error, but they should also be durable and secure. Furthermore, they should not interfere with worker tasks or inhibit lubrication. A good machine guard should also not allow any moving parts to be accessed without the guard being in place. If the guard is not in place, the worker may find it difficult to perform their duties and risk injury.

Lastly, fixed guards are the most popular type of machine guards. These are permanently attached to the machine, and they do not move while in use. This type of guard should be able to withstand high levels of vibration and contain all points of contact with hazards. In addition, it should be made from a substantial material, such as sheet metal, bars, wire cloth, or plastic. These guards can be made of a variety of materials, and are suitable for high-volume repetitive operations.

Adjustable

Adjustable guards can provide a barrier that adjusts to accommodate different stock sizes. Unlike fixed guards, however, the adjustable one is subject to human error and could come out of adjustment at any point. This type of guard requires frequent adjustments and may not provide sufficient protection for operators. Fortunately, there are a number of commercially available products designed to meet the requirements of the USP. But, you should still be sure to follow the manufacturer’s instructions to ensure your guards are in good working order.

Adjustable guards are available in two types: fixed and adjustable. The first type is a permanent part that does not move with the machine. The latter type is typically preferred because it allows for greater flexibility in stock size and allows for minimal maintenance. However, fixed guards may not be adjustable and may limit visibility. Alternatively, they may need to be disassembled to perform maintenance or prevent the machine from being cycled.

Another type of adjustable machine guard is the PFR 02, which is always in stock. This guard is multi-adjustable, and offers complete all-round protection. It is most commonly used to protect Bridgeport Milling Machines. It is made of polycarbonate, which offers excellent visibility and resistance to impact. Additionally, the PFR 02 has a flexible mounting arm that allows it to be adjusted for height and depth.

Self-adjusting guards, on the other hand, automatically adjust based on the size of the material to be inspected. When an operator presses a button, a small section of the guard moves away, creating a wider opening for the workpiece. The guard returns to its rest position when the material is removed. Self-adjusting guards are often found on table saws and woodworking tools. In addition to adjustable guards, self-adjusting ones can be easily installed on machines, too.

Self-adjusting

Self-adjusting USA machine guards are an excellent way to protect your workers. These guards automatically adjust based on the movement of a stock. The operator simply moves the stock into the danger zone, and the guard moves away and back into position. Self-adjusting USA machine guards are made of metal, plastic, or other substantial materials. However, they can cause vision problems and require frequent maintenance. Furthermore, they do not always provide the maximum level of protection.

The self-adjusting USA machine guards work in the same manner as adjustable options. These guards automatically adjust to different sizes of materials, but no employee assistance is required. They naturally change size based on the amount of products that are sent through them. In addition, self-adjusting USA machine guards are easier to use than adjustable guards because there are no lock-out mechanisms to prevent the operator from removing them. These guards also tend to last longer than fixed models, so they can save you money and time in the long run.

Machine guards should be made of durable materials. Whether they are made of plastic or metal, they must withstand the extreme conditions associated with machine operation. These guards should withstand large movements and high temperatures. Additionally, they should firmly attach to the machine. They should not become loose during operation, and they should be difficult to remove if necessary. Self-adjusting USA machine guards should also be hardy and secure, meaning that they will withstand any force that a machine can exert on it.

Fixed guards are an excellent option if you’re looking for maximum protection. Unlike adjustable guards, fixed machine guards move while the machine is in operation. Hence, they’re an excellent choice if you’re looking for a machine guard that protects employees from moving parts. These guards may need moving parts and may not be suitable for all applications. Nevertheless, they’re still an effective and convenient way to protect your employees.

Omron STI

For the safest and most effective way to protect your employees around dangerous machines, consider Omron STI’s universal safety mat system. The UM series safety mat combined with the MC3 and MC4 models will give you the freedom to move freely around the machines while minimizing operator fatigue. The Omron STI Safety Interlock Switches work in conjunction with machine guards to prevent power loss if the guards are opened. They also feature a laser scanner that detects intrusion to the protective field.

In addition to the Omron STI safety products, Omron offers many other safety solutions, including programmable safety controllers and safety barriers. Safety is of utmost importance in an automated factory environment, and Omron STI USA’s machine guards and safety barriers are an important component of these systems. The company has received global recognition for its safety products and is a leader in safety education and risk assessment.

Get More information:

How to Pick a Retirement Community: Everything You Need to Know

A Beginner’s Guide to Testosterone Enhancement Options

Housing Market Outlook and Predictions

The Benefits of Chiropractic Care After a Car Accident

8 High-Risk Investments that Could Change Your Life

How Old Is Snoop Dogg | basic info Snoop Dogg life

Frequently Asked Questions about aainflight American Airlines